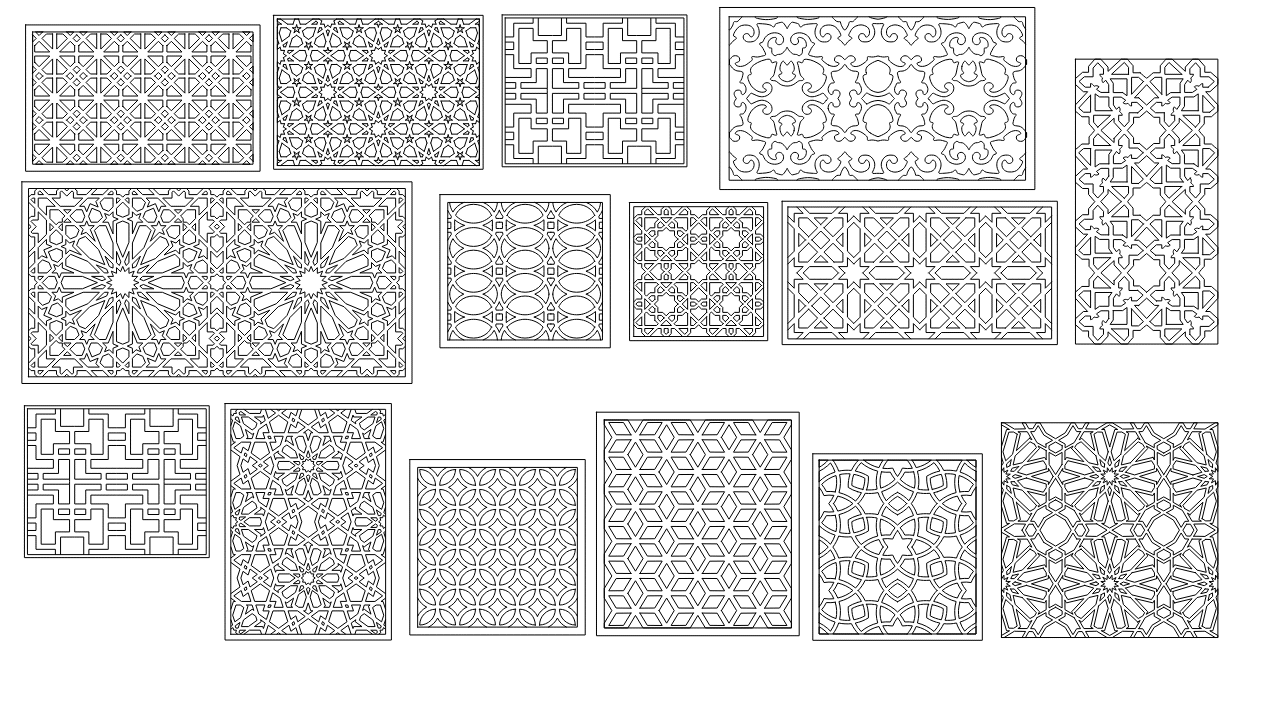

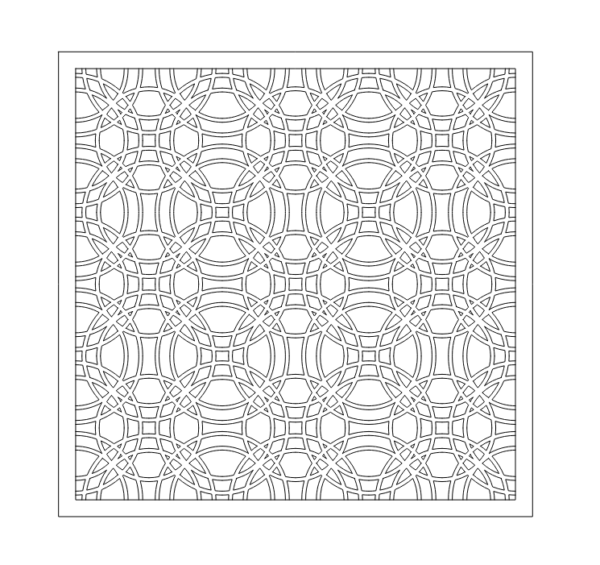

Jali cutting 15 patterns design for CNC laser and router cutting DXF Vector File

₹419.85

Description

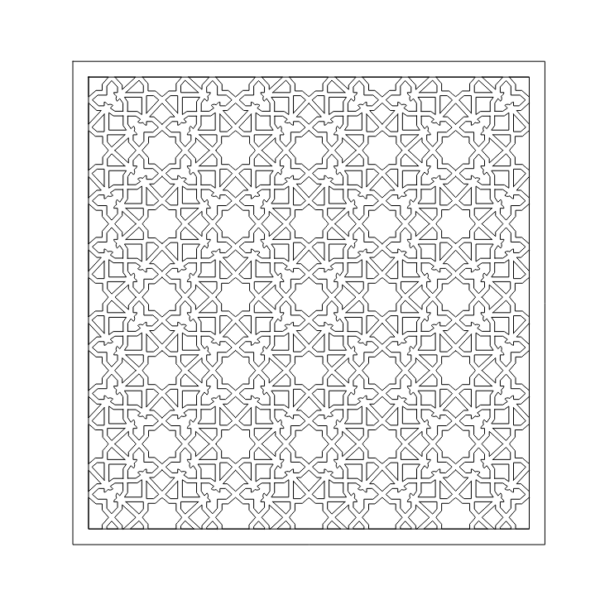

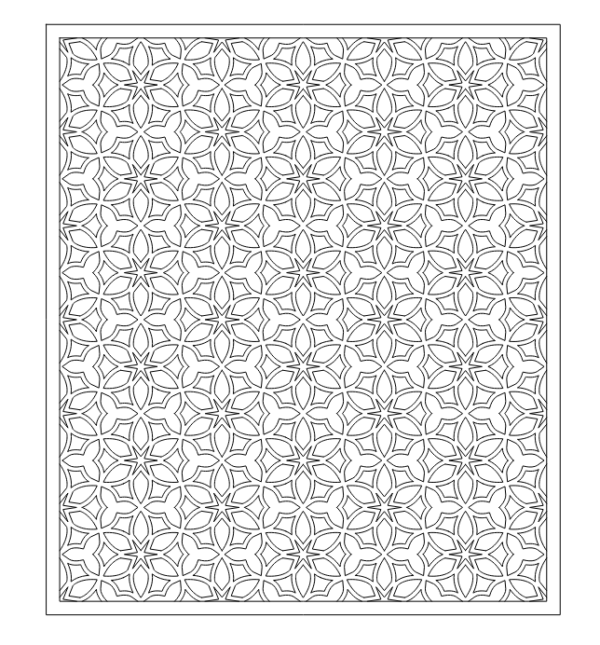

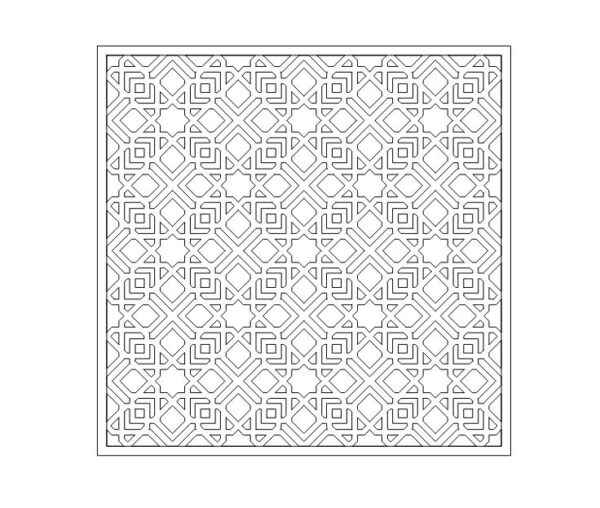

Jali cutting, also known as lattice or fretwork, involves intricate patterns or designs typically used in architecture, interior design, or woodworking to create decorative screens, panels, or partitions. These patterns are often characterized by their geometric complexity, floral motifs, or cultural symbolism.

When creating Jali cutting designs for CNC (Computer Numerical Control) laser and router cutting, it’s crucial to ensure the DXF vector file is optimized for precision and efficiency in manufacturing. Here’s a breakdown of what a description for such a file might include:

- Design Overview: Briefly describe the overall aesthetic or theme of the Jali patterns. For instance, it could be inspired by traditional Islamic, Indian, or modern geometric designs.

- Pattern Complexity: Mention the intricacy of the patterns, whether they involve delicate filigree work, intricate interlocking shapes, or repeating geometric motifs.

- Scale and Dimensions: Specify the dimensions of the design, including width, height, and thickness, as well as any scalability options for resizing without losing quality.

- File Format: Clearly state that the file is in DXF (Drawing Exchange Format), which is compatible with most CAD (Computer-Aided Design) and CNC software.

- Compatibility: Ensure compatibility with CNC laser and router cutting machines, specifying any specific requirements or limitations regarding cutting parameters, such as material thickness and machine capabilities.

- Layer Organization: Organize the design elements into layers for ease of editing and manufacturing, including separate layers for cutting paths, engraving, and any additional features.

- Quality Assurance: Highlight any quality control measures taken to ensure precision and accuracy in cutting, such as testing the design on prototype materials or conducting virtual simulations.

- Usage Recommendations: Provide guidance on suitable materials for fabrication, such as wood, acrylic, metal, or composite materials, along with recommendations for finishing and assembly.

- Customization Options: Mention whether the design can be customized or modified to suit specific project requirements, such as adjusting the scale, orientation, or adding personalized elements.

- Documentation and Support: Include any supplementary documentation, such as assembly instructions or technical support contacts, to assist users in implementing the design effectively.